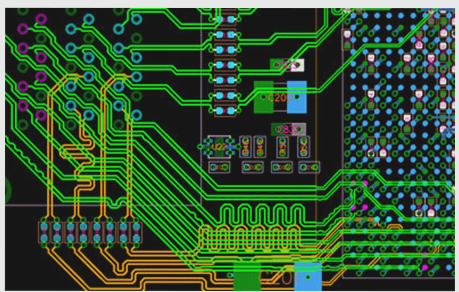

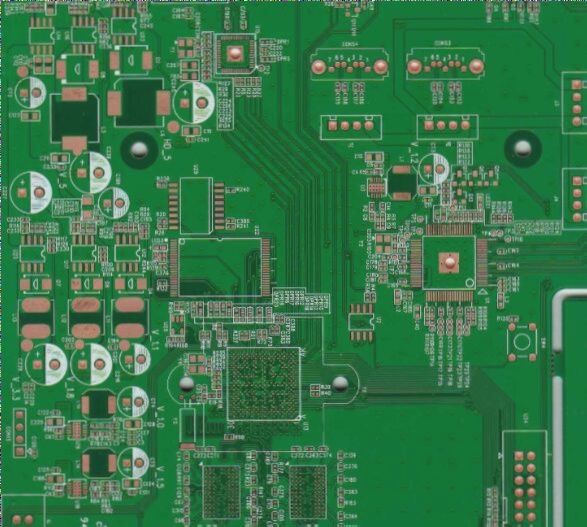

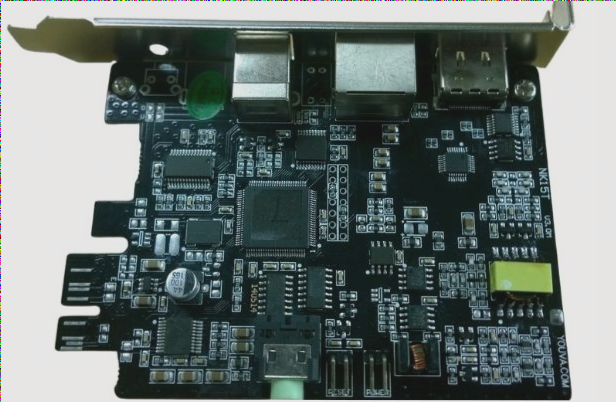

PCB Plated Hole Filling Technology

The global electroplating PCB industry is rapidly growing, driven by the need for advanced hole filling solutions like electroplating to enhance electrical performance, heat dissipation, and via stacking, with key factors such as anode type, cathode-anode distance, current density, and substrate material influencing the process.