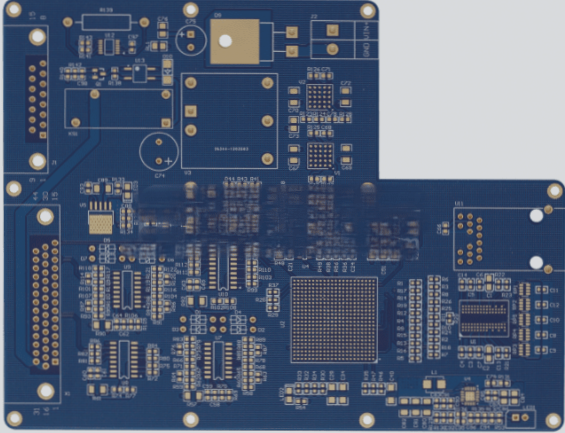

Set the edge width for the PCB process in automotive circuit board manufacturing.

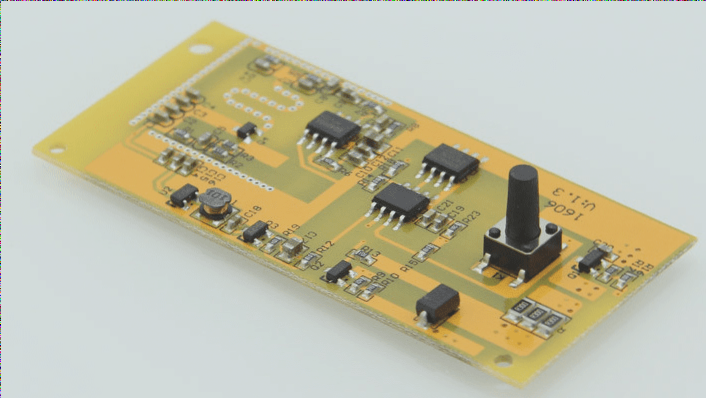

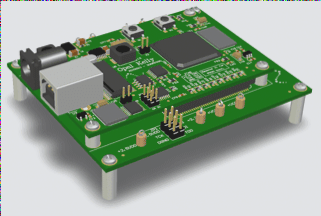

In PCB manufacturing, reserving process edges is essential for SMT processing, aiding in production while balancing cost and operability, with specific considerations for design, splicing, and component placement to ensure efficient assembly and quality.

Set the edge width for the PCB process in automotive circuit board manufacturing. Read More »