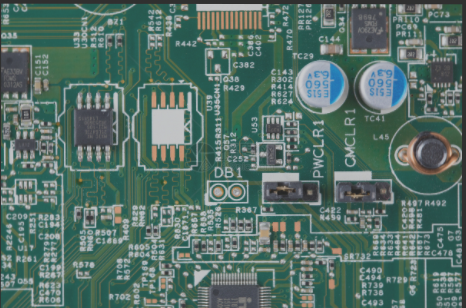

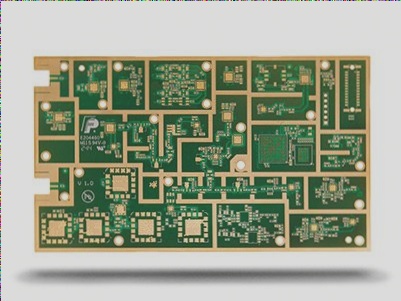

Methods to Mitigate PCB Circuit Board Deformation

This article discusses the causes, hazards, and strategies for minimizing PCB warping and deformation during reflow soldering, emphasizing the importance of material selection, manufacturing processes, and design optimization to ensure high-quality and reliable circuit boards.

Methods to Mitigate PCB Circuit Board Deformation Read More »