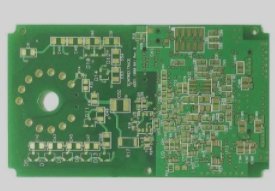

Proficient in PCB solder paste printing techniques and board preparation.

The PCB solder paste printing process relies on the precise interaction of three key elements—solder paste, stencils, and squeegees—along with careful control of variables like pressure, speed, and separation distance, to ensure consistent and high-quality print results.

Proficient in PCB solder paste printing techniques and board preparation. Read More »