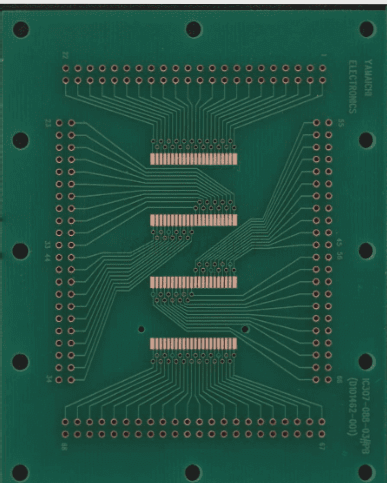

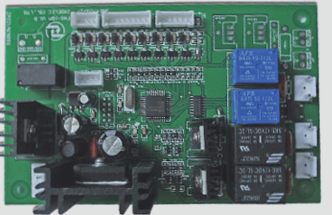

The methods of PCB fabrication are as follows.

The methods of PCB processing, including shearing, punching, blanking, and milling, play a key role in meeting environmental standards and the growing demand for high-performance electronic devices, with advanced techniques ensuring precision and reliability in the production of PCBs and PCBA products.