EMC Interference Issues in PCB Design

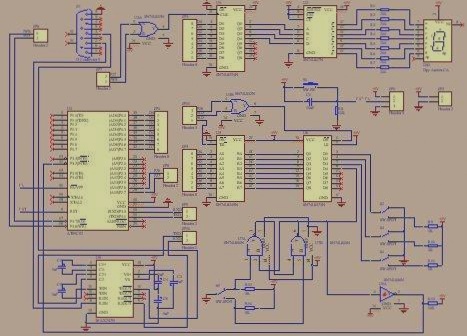

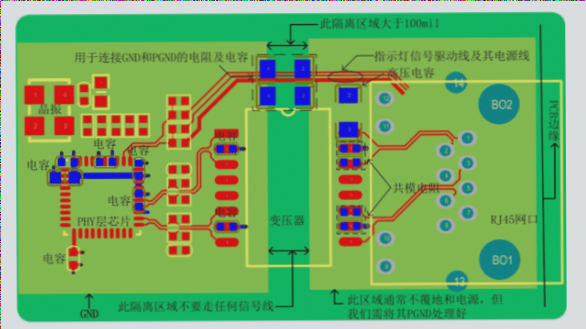

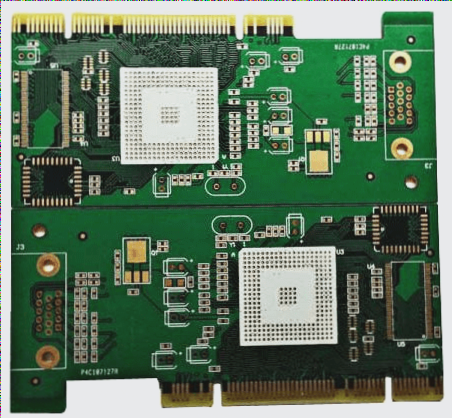

Electromagnetic compatibility (EMC) in PCB design involves minimizing electromagnetic emissions and shielding the system from external interference by managing interference sources, propagation paths, and enhancing component immunity to ensure reliable, interference-free operation.