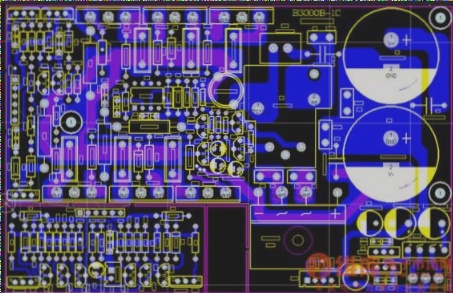

Minimize rework to enhance PCB reliability.

The rework temperature for PCB assemblies should be carefully controlled, as it differs from reflow soldering temperatures due to localized heating, component size, and the need for rapid cooling to ensure strong solder joints. Preheating methods, including ovens, hot plates, and hot air slots, each have their advantages and limitations, with rapid cooling after reflow being crucial to prevent defects and maintain joint strength.