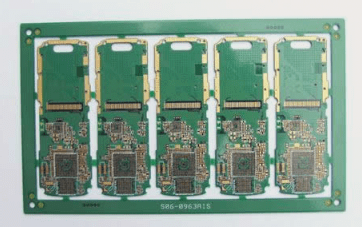

Specifications and Requirements for the PCB Silk Screen Printing Process

The PCB screen printing process consists of two main stages—drawing and drying—covering several detailed steps such as screen preparation, mesh tensioning, gluing, film application, and specification adherence to ensure high-quality, precise PCB production.

Specifications and Requirements for the PCB Silk Screen Printing Process Read More »