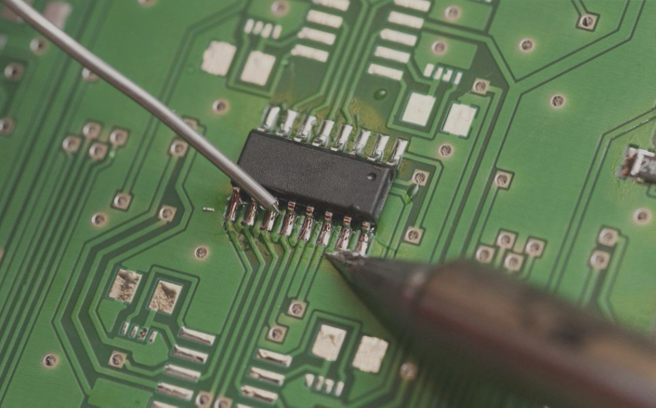

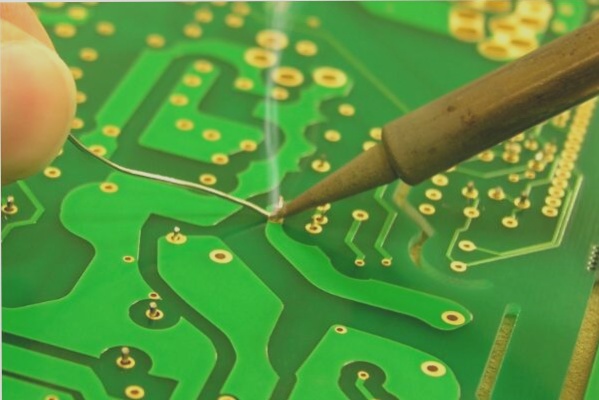

Manual PCB soldering using a soldering iron

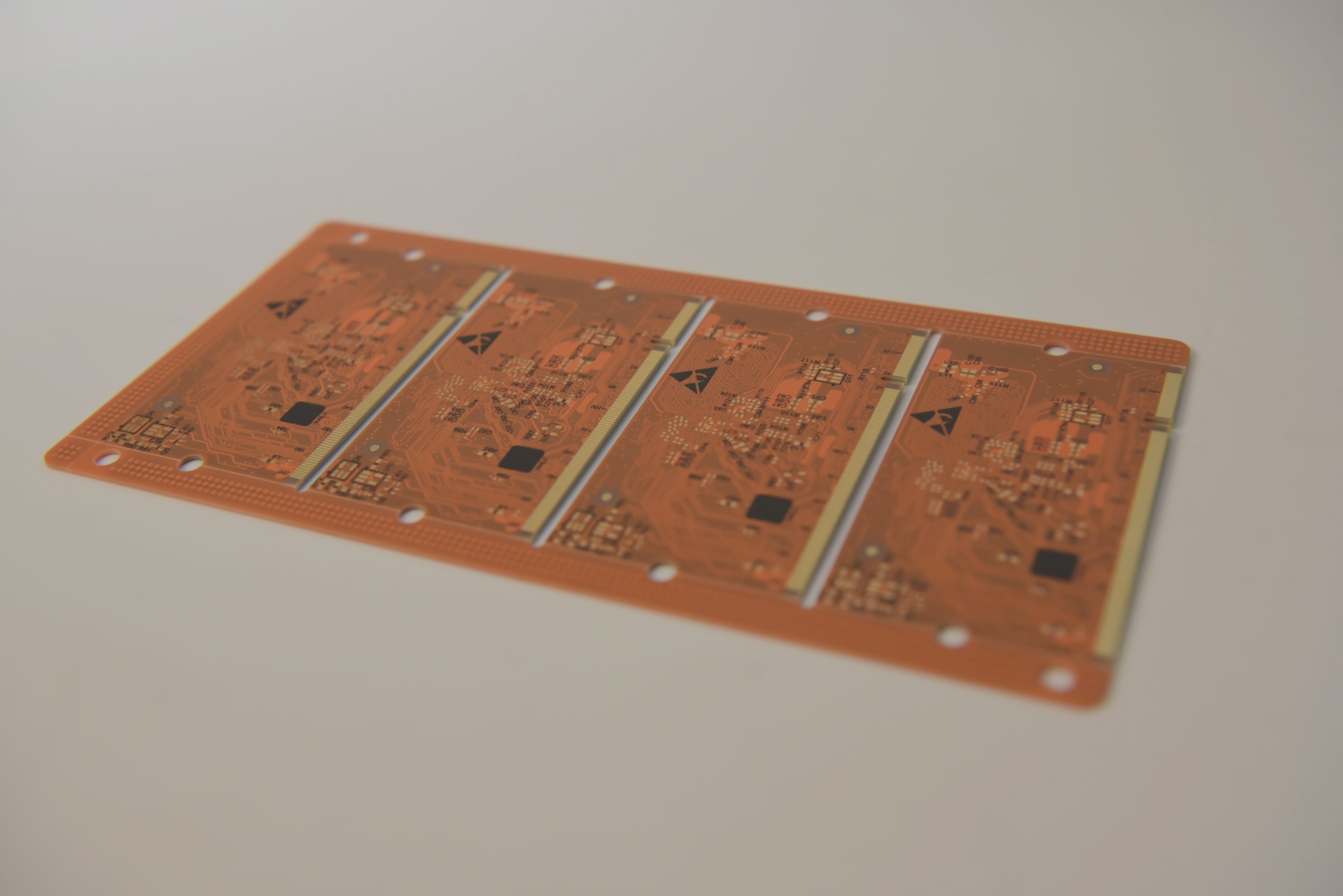

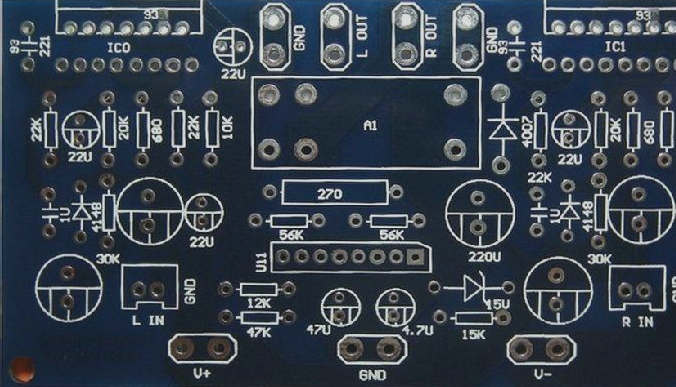

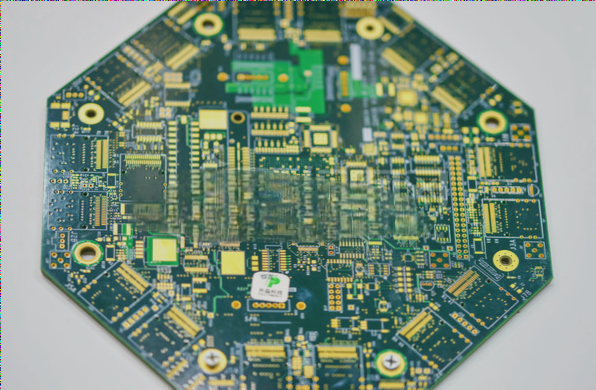

A comprehensive guide on PCB soldering that covers both the proper techniques for using a soldering iron and essential maintenance practices to ensure high-quality solder joints and the longevity of both the soldering iron and PCB components.