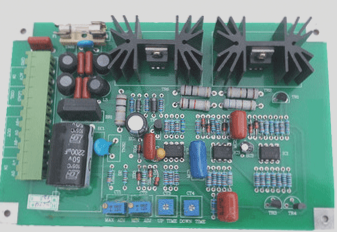

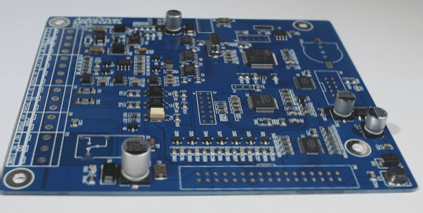

PCB tin plating using HASL and organic solderability preservative (OSP) for anti-oxidation

PCB surface treatment technology involves creating a protective layer to enhance solderability and electrical performance, with common methods including HASL and OSP, each addressing issues like oxidation, cost, and environmental regulations.