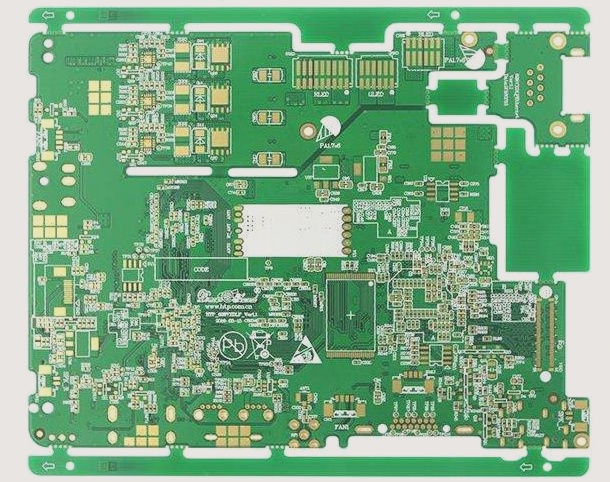

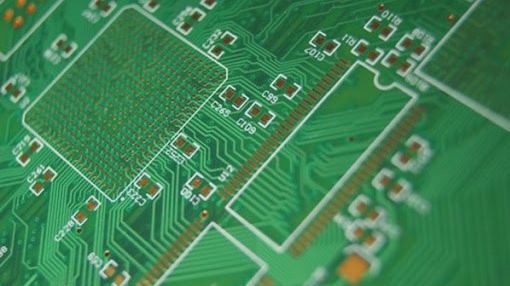

The evolution of electronic products toward smaller, denser designs has driven the demand for advanced PCBs, especially those using SMT and BGA technologies. As a result, hole plugging is crucial during component mounting to prevent solder from causing short circuits during PCB wave soldering. This process also prevents flux residue buildup, ensures vacuum sealing after component assembly, and maintains solder integrity on the board surface, crucial for reliable electronic performance. Achieving these goals involves intricate processes, such as hot air leveling and various hole-plugging techniques, tailored to meet stringent customer specifications and ensure high-quality PCB production.