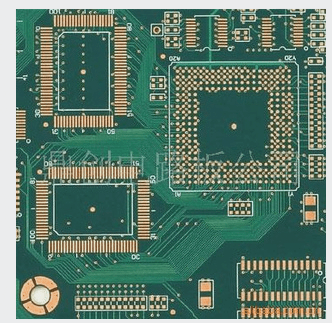

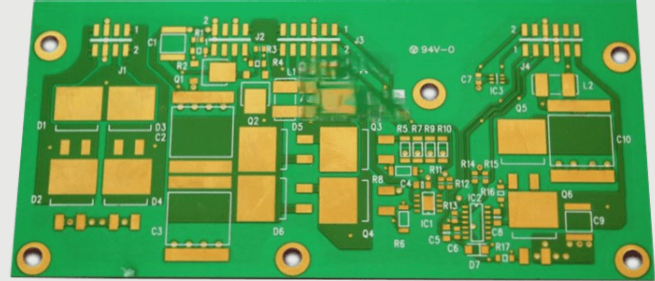

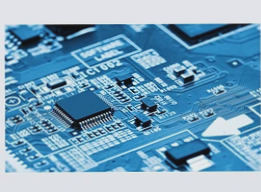

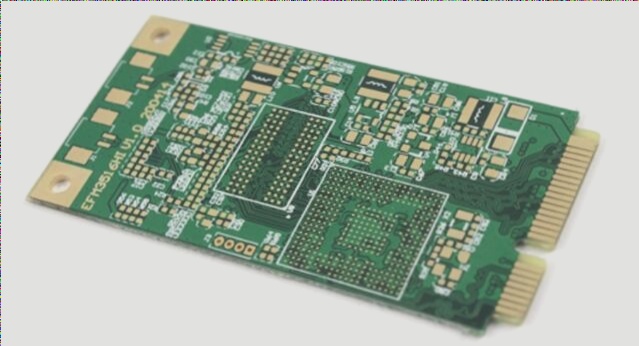

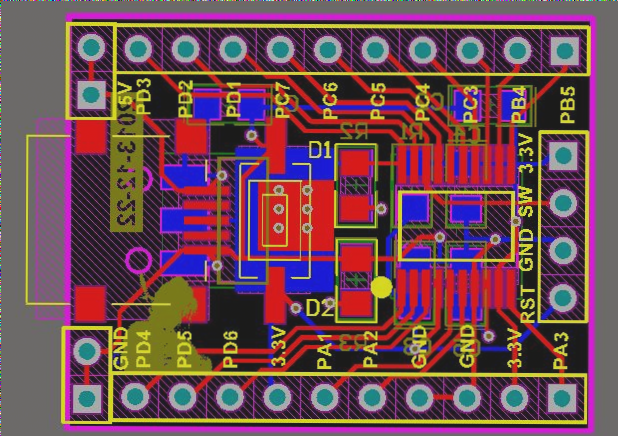

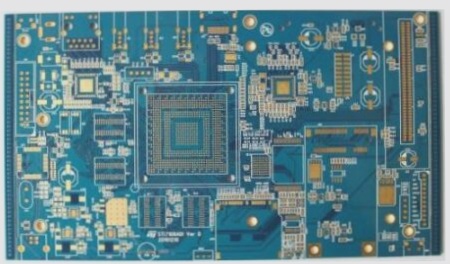

Key Considerations in PCB Layout Design

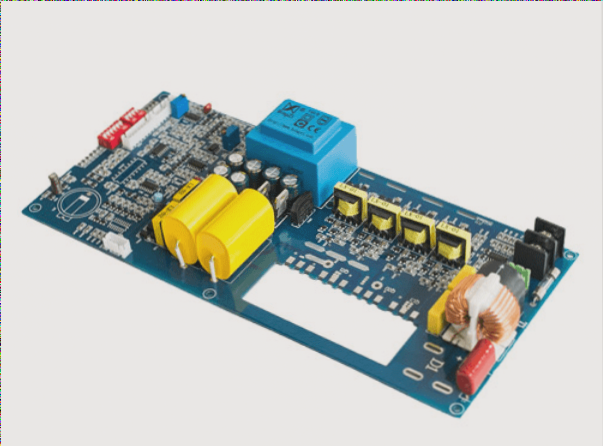

In PCB design, after wiring is completed, it’s crucial to adjust layouts and apply copper carefully to avoid signal issues and ensure effective production and maintenance, while also considering grounding to prevent interference and overheating during soldering.