The Impact of Humidity on PCBA Manufacturing Process

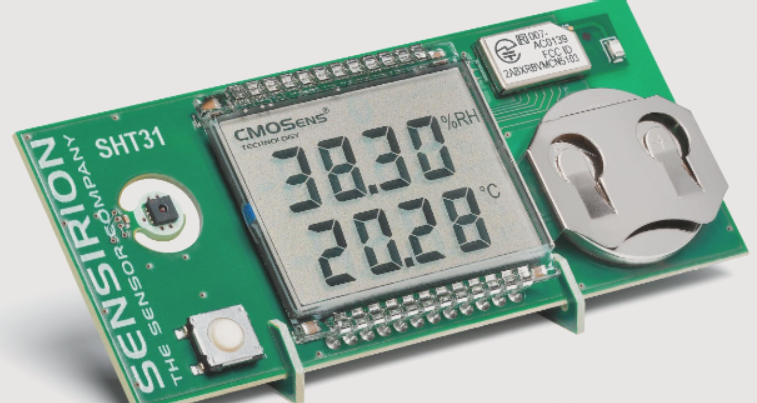

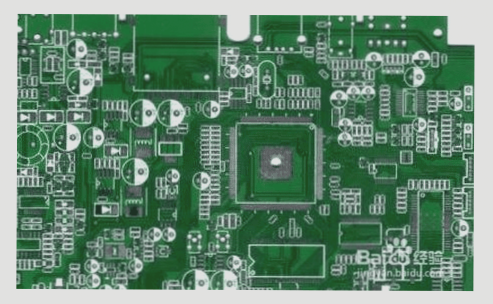

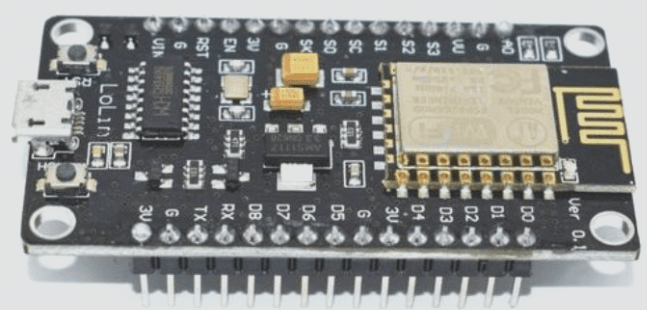

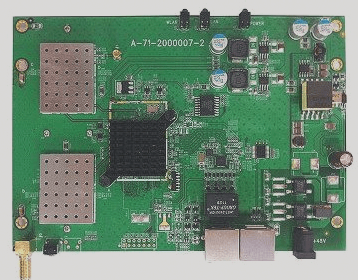

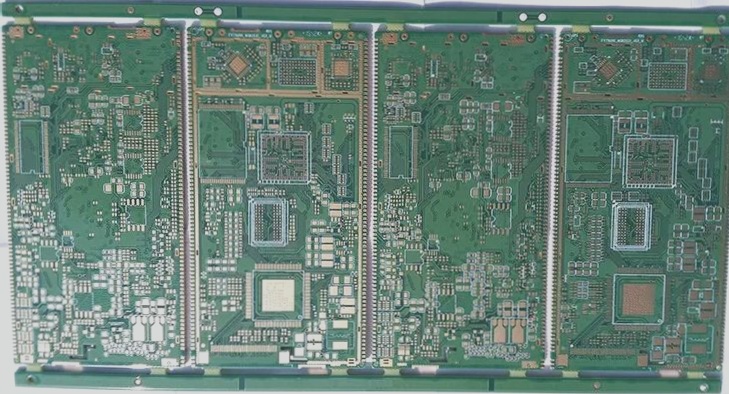

Humidity significantly affects PCBA manufacturing, with low humidity increasing electrostatic discharge and friction-related issues, while high humidity causes moisture absorption, leading to defects like delamination and poor soldering, making precise humidity control essential for ensuring production quality and reliability.

The Impact of Humidity on PCBA Manufacturing Process Read More »