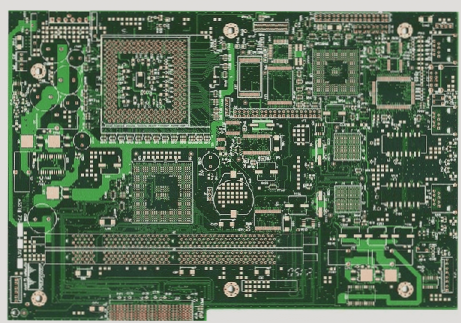

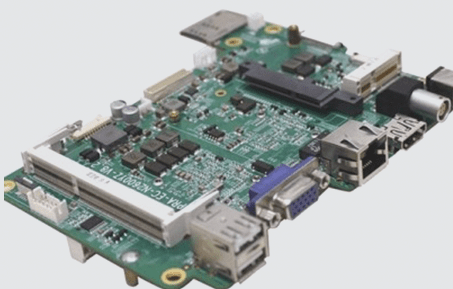

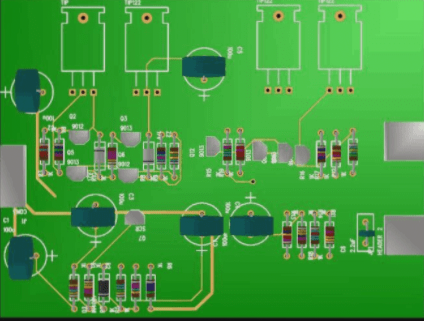

Causes of Material Discard in PCBA and Proposed Solutions

PCBA circuit board processing is essential for electronic devices, with quality directly affecting functionality, and common challenges include issues with nozzles, feeders, recognition systems, and programming, all requiring targeted solutions to minimize rejection rates and enhance production efficiency.

Causes of Material Discard in PCBA and Proposed Solutions Read More »