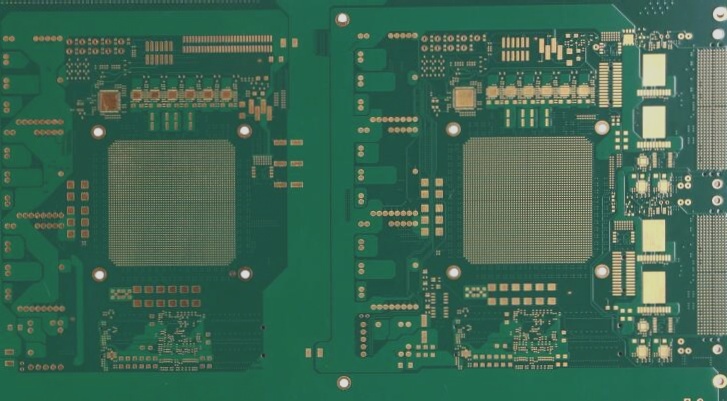

Factors Leading to Detachment of Copper Traces on Impedance-Controlled

Copper wire detachment on impedance circuit boards can be attributed to issues such as over-etched copper foil, residual etching solution, unreasonable circuit design, abnormal electrolytic copper foil, and poor etching of potion. Selecting a manufacturer with robust process capabilities and quality materials can help mitigate this problem.

Factors Leading to Detachment of Copper Traces on Impedance-Controlled Read More »