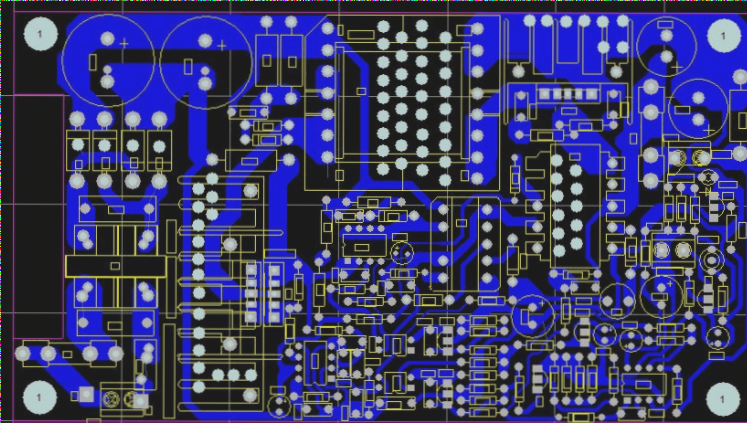

During PCB fabrication: What auxiliary materials are utilized in the COB bonding process?

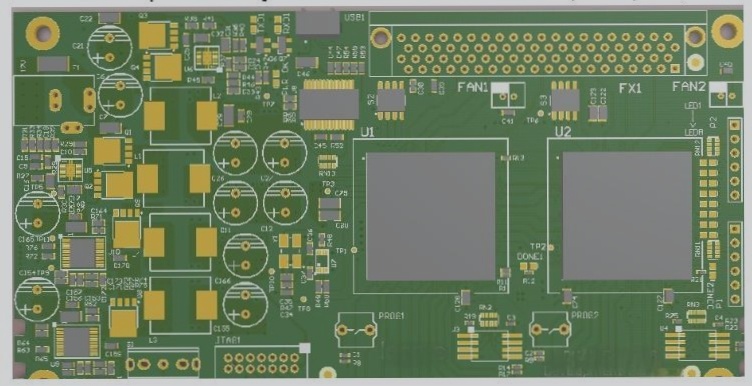

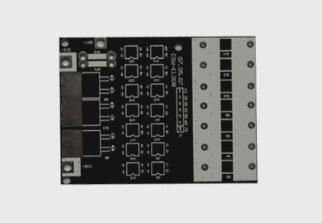

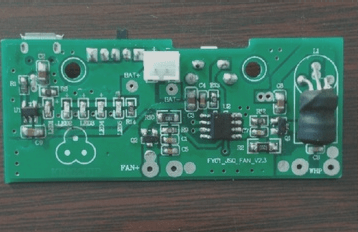

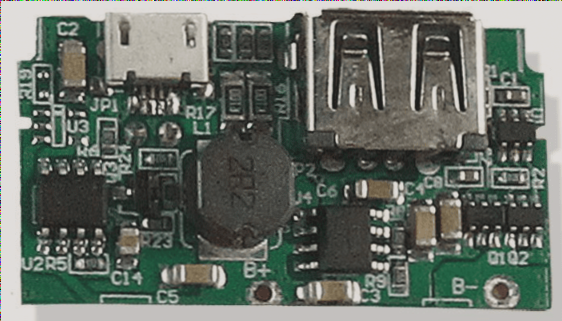

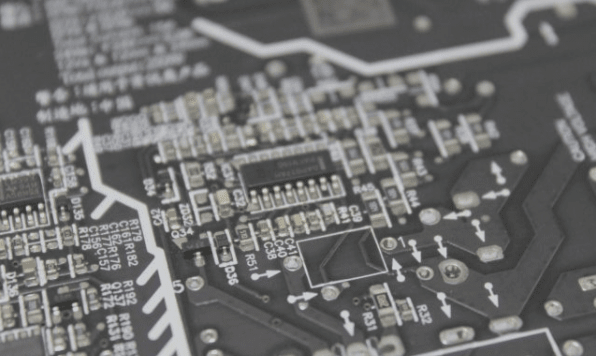

COB bonding processing involves attaching IC die wafers to PCBs using specialized techniques, including aluminum wire connections and adhesives, while ensuring the use of appropriate PCB finishes and managing costs effectively.