Processing techniques for PCB pads and utilization of FPC materials

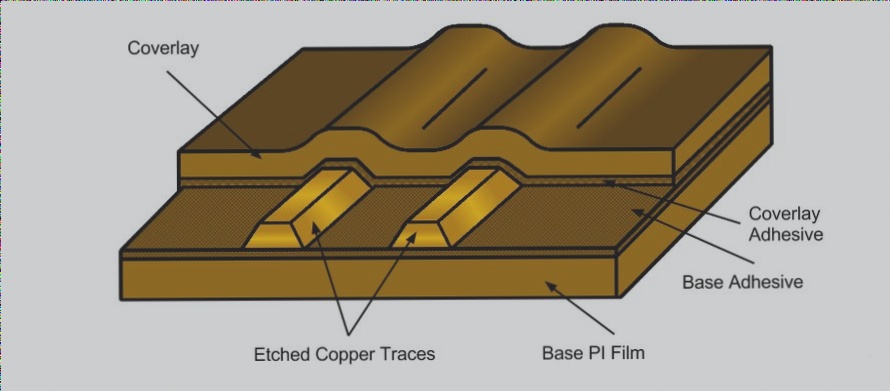

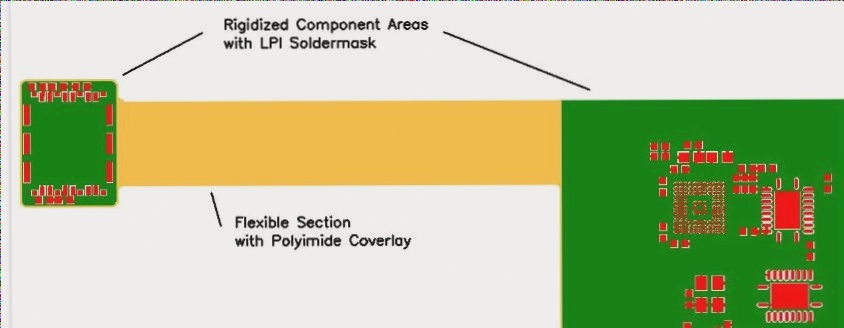

FPC, or flexible printed circuit, utilizes a flexible substrate like polyimide or polyester, allowing it to bend or fold for diverse applications, often protected by a cover layer. Connections to PCBs employ methods such as ENIG, tin-lead, SEG, OSP, and HASL, balancing technical advantages with environmental considerations.

Processing techniques for PCB pads and utilization of FPC materials Read More »