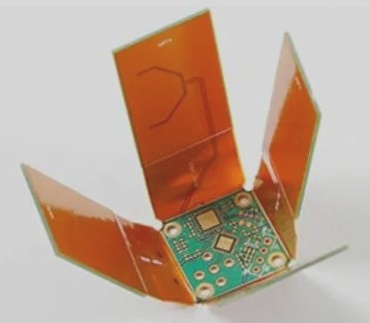

The Significance of Electroplating in PCB Manufacturing

Copper is commonly used on printed circuit boards for interconnecting components, but requires protection from oxidation and corrosion through technologies like organic paint, oxide film, and electroplating, with gold being a common plating material for high wear resistance and low contact resistance.

The Significance of Electroplating in PCB Manufacturing Read More »