6-layer PCB Exposure Imaging

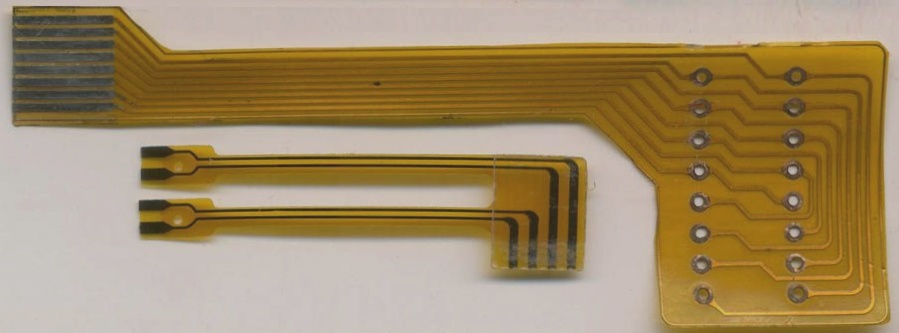

Circuit diagrams are designed and printed on transparent film or translucent paper, utilizing a laser or inkjet printer, followed by careful attention to exposure times and development processes to ensure high-resolution outcomes.