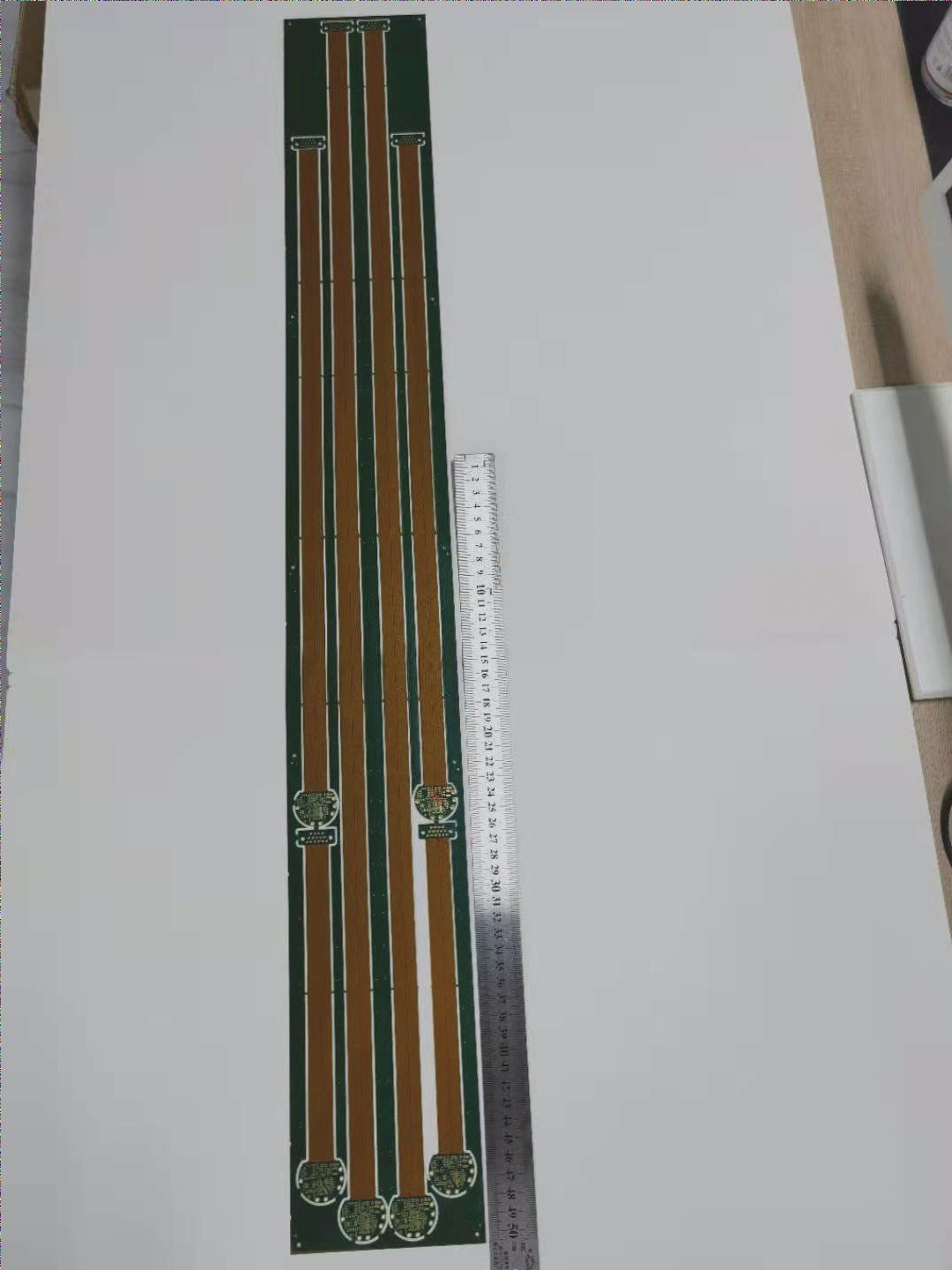

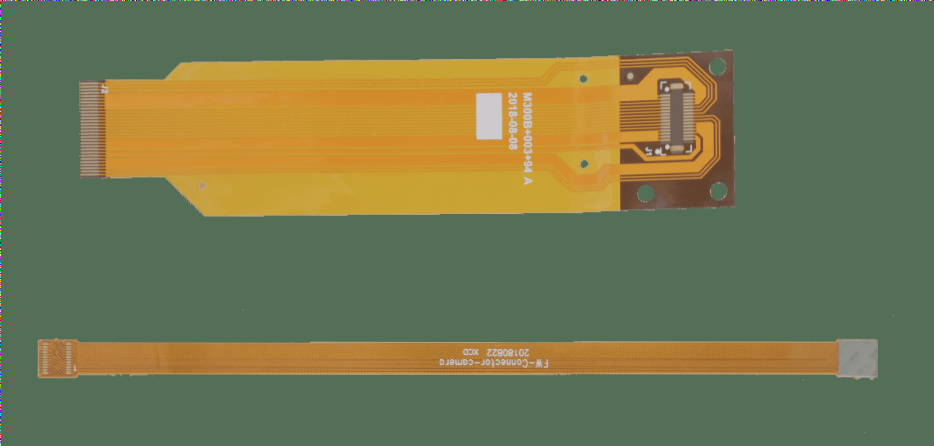

PCB electronic circuit board manufacturing process

The PCB industry operates on customer orders and requires ongoing adjustments throughout production due to changes in client demands, involving complex planning and scheduling, as well as intricate processes for material handling and component integration.

PCB electronic circuit board manufacturing process Read More »