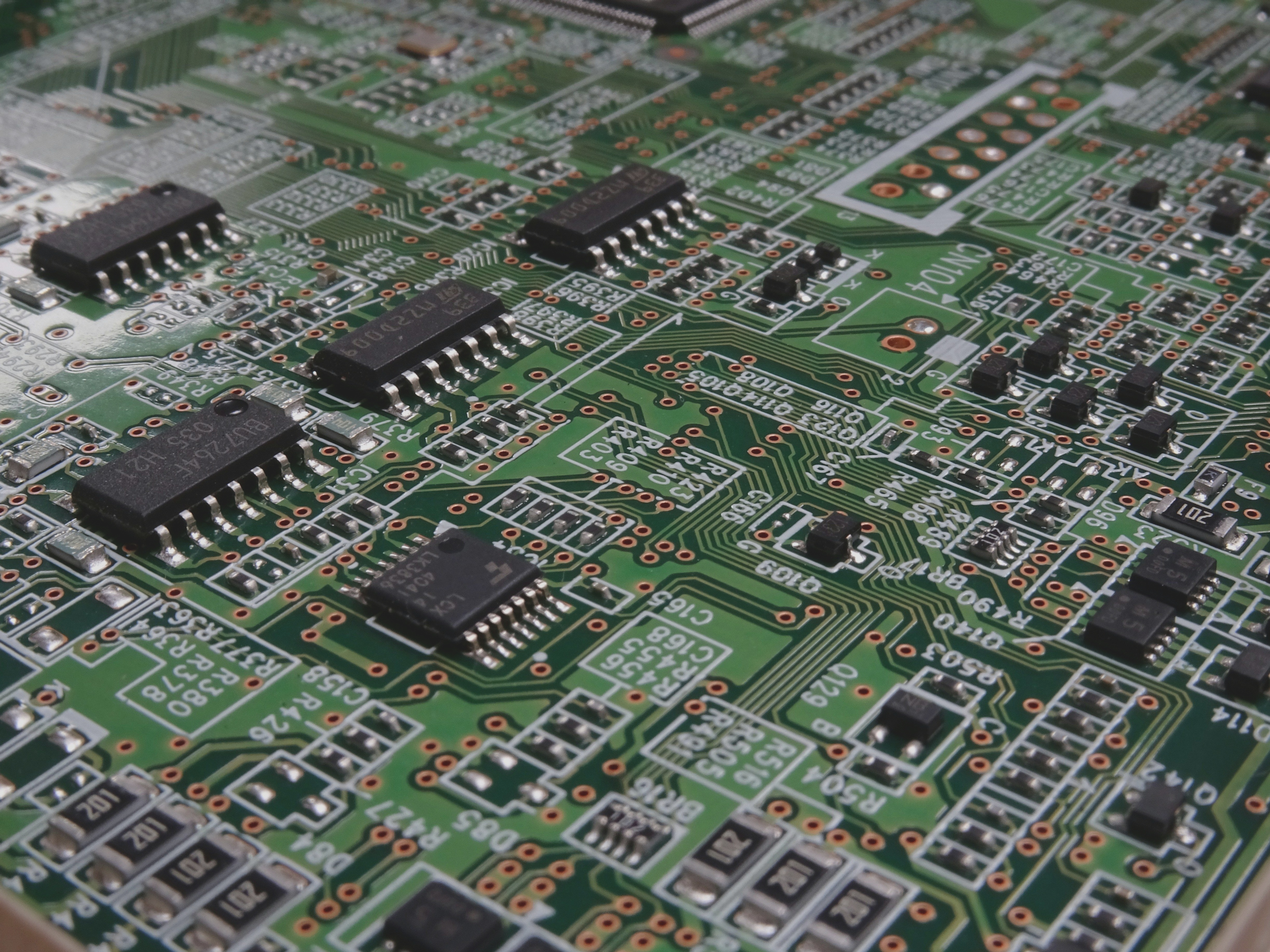

Key Elements of a Professional PCBA Manufacturing Team

The success of a professional PCBA production team depends on a combination of technical expertise, advanced equipment, rigorous quality control, efficient project management, effective communication, a customer-centric approach, seamless collaboration, and a continuous improvement mindset.

Key Elements of a Professional PCBA Manufacturing Team Read More »