How to Select a PCBA Assembly Manufacturer?

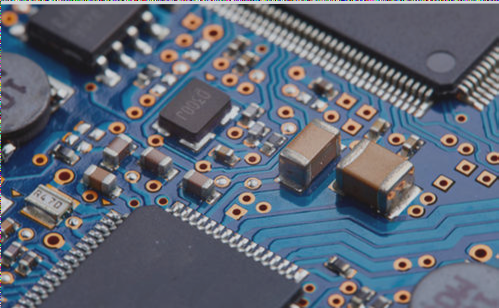

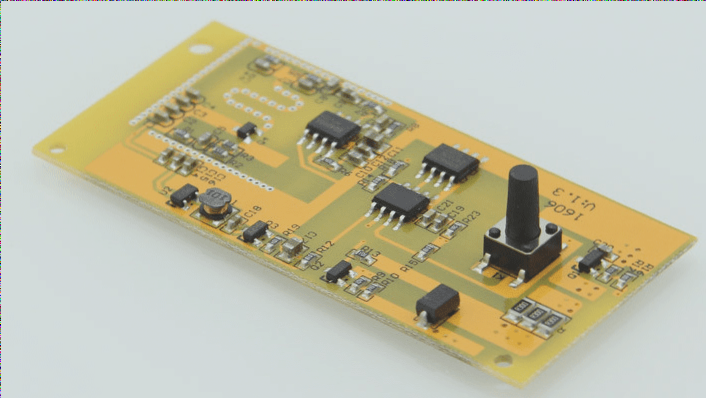

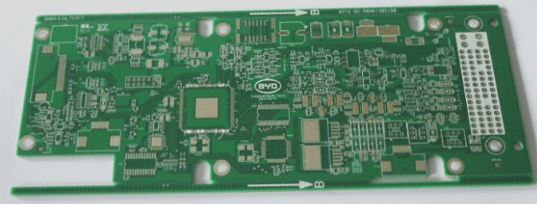

When choosing a PCBA assembly manufacturer, consider factors like machine condition, quality inspections, production capacity, component inventory, solder paste handling, operator skill, lead vs. lead-free production lines, defect rates, and material storage practices to ensure quality and efficiency.