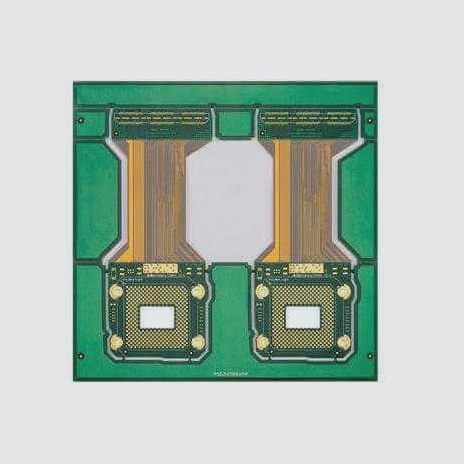

1. Collaborating with a turnkey PCB fabricator offering assembly services expedites delivery, reduces costs, and ensures comprehensive communication, crucial for selecting a Chinese rigid-flex PCB manufacturer. 2. When choosing a manufacturer, evaluate their capabilities thoroughly, focusing on key parameters like thickness, impedance control, and production capacity to avoid potential disasters, especially in volume orders. 3. Effective communication is paramount when dealing with Chinese rigid-flex PCB manufacturers due to time-zone and language differences, necessitating extra attention during supplier selection. 4. Incorporating elements like buried microvias, thin final thickness, layered configurations, and HDI designs ensures optimal performance and reliability in rigid-flex PCBs.