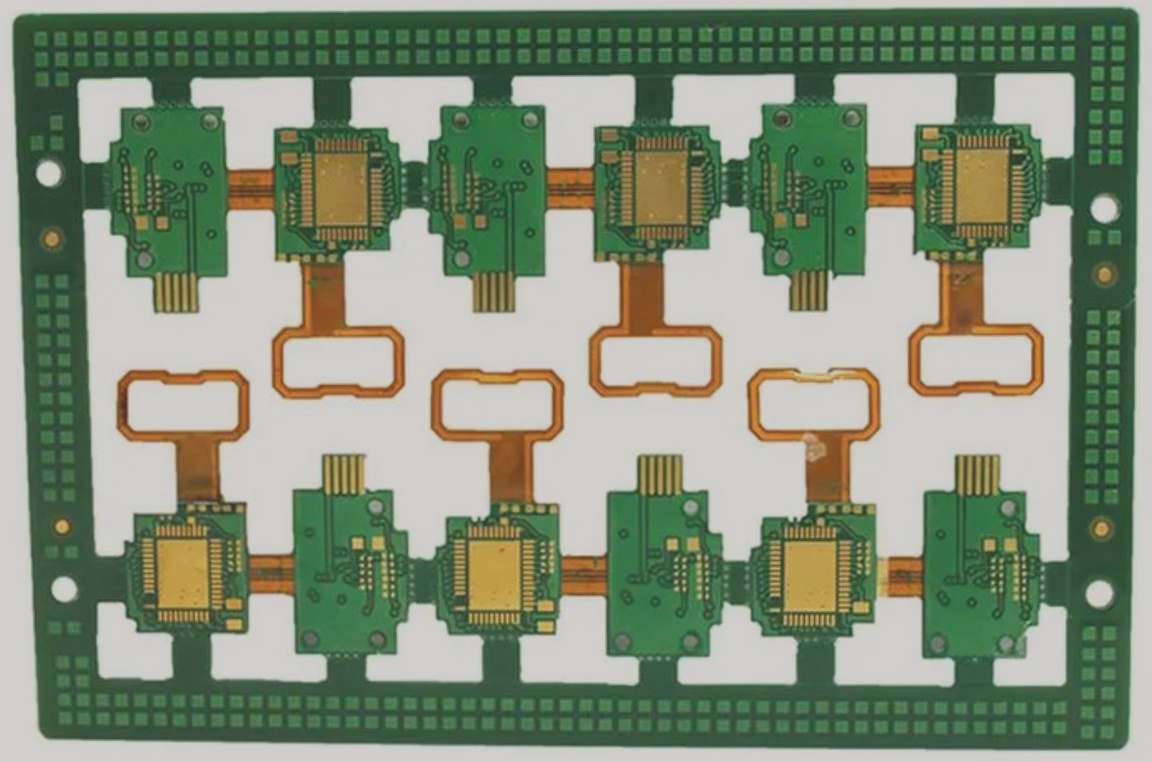

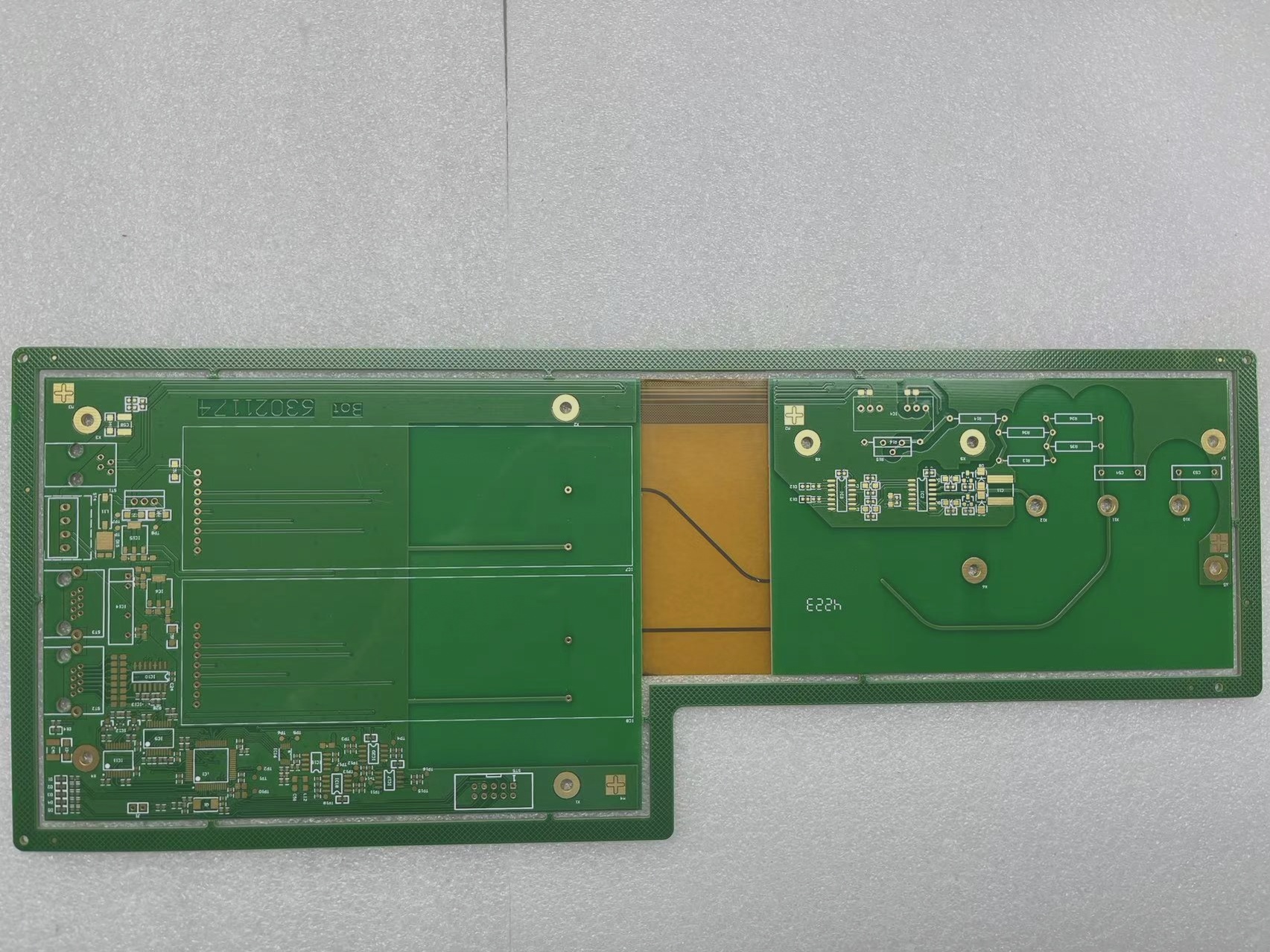

Rigid-Flex PCB Design Tutorial

The design of Rigid-Flex PCB can be complex, involving considerations of signal direction, energy transfer, and heat effects, with key aspects summarized as “how to place” and “how to connect” with critical attention to signal line priority and density first principle.