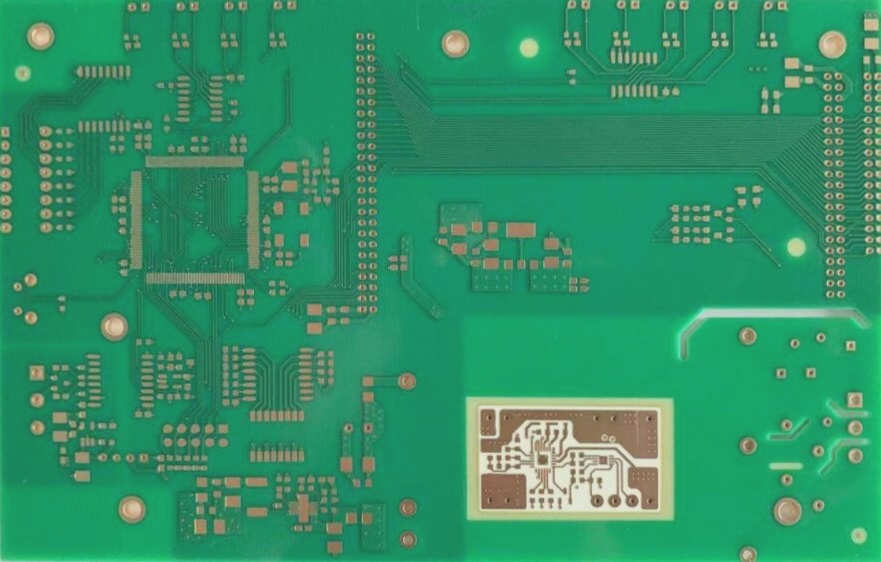

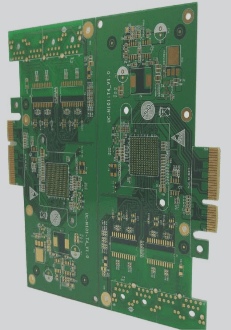

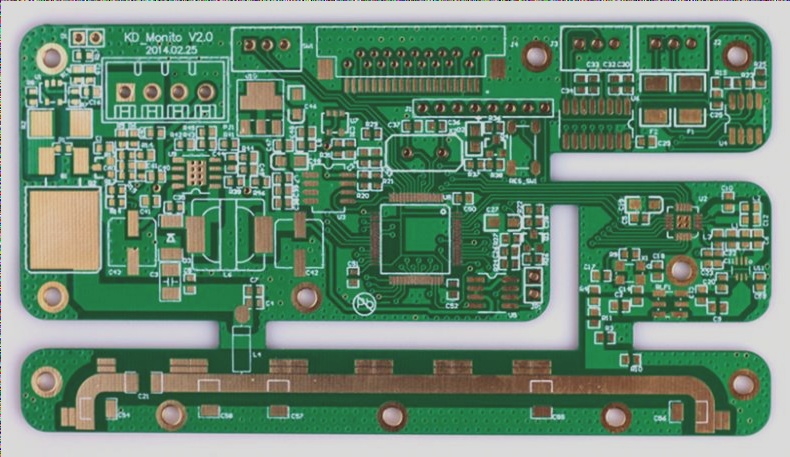

Global Vision Technology implements PDCA management improvement guided by ISO9001 standards, refining internal processes and supply chain management to provide quality manufacturing services. This includes rigorous oversight of process design, DFM inspection, PCBA manufacturing, and personnel training, ensuring a robust quality management system. Additionally, DFM inspections ensure thorough checks of design elements, while new product introduction meetings streamline communication and planning across departments. PCB board oversight guarantees quality through collaboration with top suppliers and strict quality control measures, while electronic components procurement follows precise specifications and formal channels, supported by original technical support.