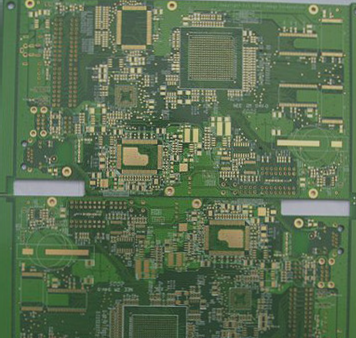

There are various through-hole plating techniques used in PCB manufacturing.

The text outlines various PCB manufacturing processes, including hole wall activation for electroplating, through-hole plating, selective plating methods like reel-linkage and brush plating, and the use of low-viscosity ink for efficient prototyping, each aimed at improving adhesion, conductivity, and efficiency in the production of printed circuit boards.

There are various through-hole plating techniques used in PCB manufacturing. Read More »