Fundamentals of PCB Design and Circuit Board Engineering

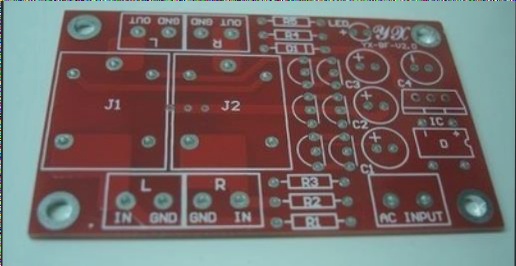

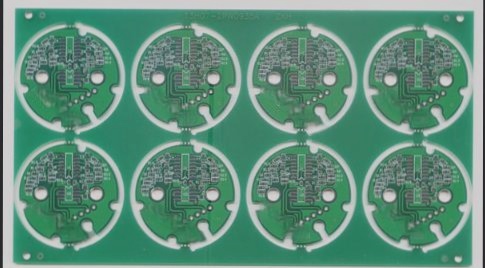

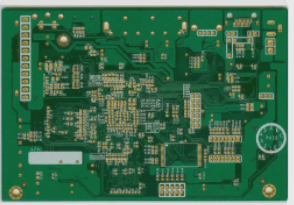

The “layers” in PCB design refer to the actual physical copper layers of a circuit board, with modern designs often including multiple layers for routing and power distribution, while concepts like vias, silk screen, SMD components, and fill areas must be carefully managed to ensure a functional and manufacturable design.

Fundamentals of PCB Design and Circuit Board Engineering Read More »