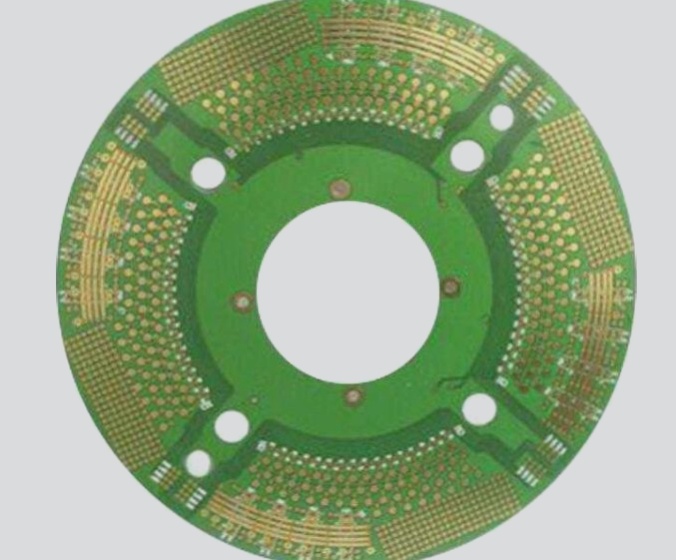

How are double-sided printed circuit boards (PCBs) manufactured?

The double-sided PCB manufacturing process includes methods like SMOBC (Solder Mask Over Bare Copper) and pattern plating, with key steps such as electroless copper plating, lead-tin stripping, hole plugging, and hot air leveling, aimed at improving solderability, reliability, and circuit integrity.

How are double-sided printed circuit boards (PCBs) manufactured? Read More »