What is the distinction between PCB fabrication and PCBA assembly?

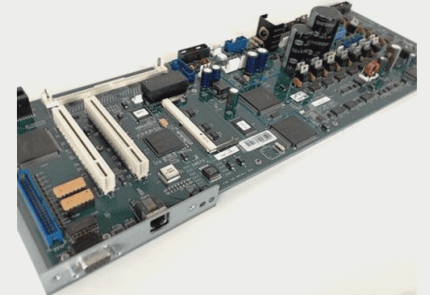

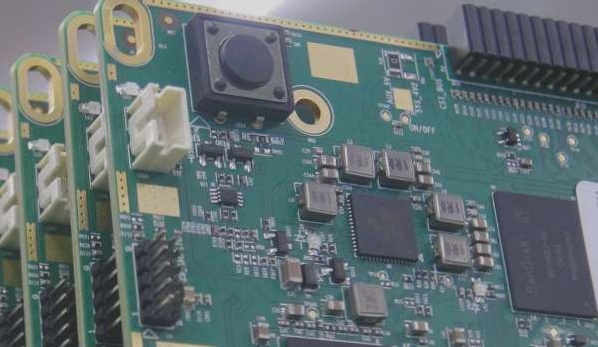

PCBA is a fully assembled circuit board with components mounted, while PCB is a bare, unpopulated board, highlighting that PCBA involves additional assembly beyond just the PCB itself.

What is the distinction between PCB fabrication and PCBA assembly? Read More »