Pixel Pump – Engineering & Technical Solutions – Wellcircuits

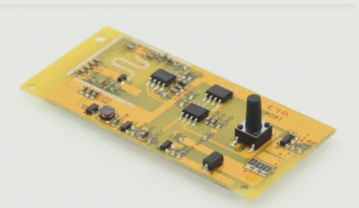

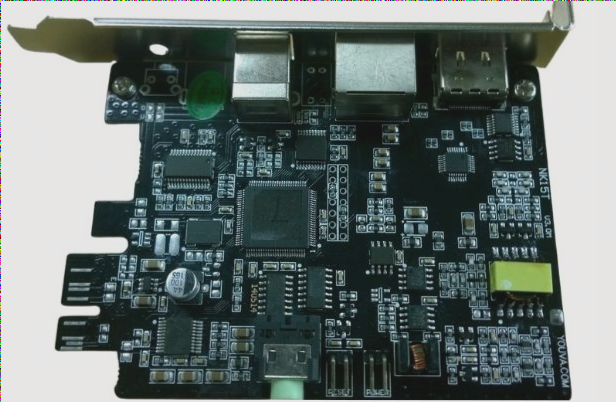

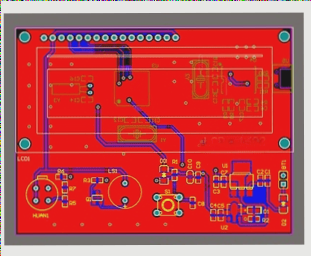

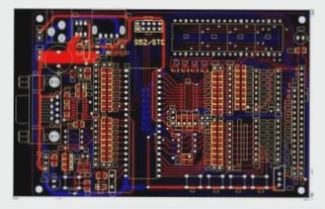

Pixel Pump is an open source vacuum pump for manual SMT assembly with a pen a foot pedal RGB LED buttons and a variety of functions that can make the process interesting It is suitable for both ind

Pixel Pump – Engineering & Technical Solutions – Wellcircuits Read More »