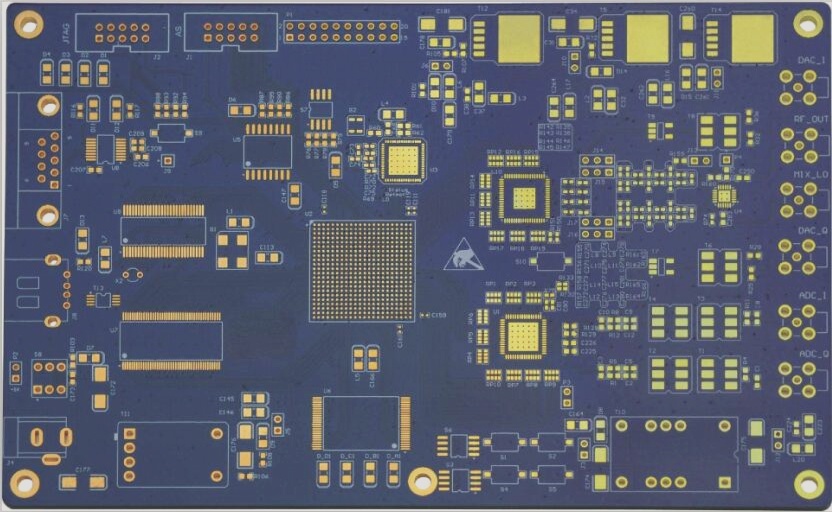

Material Description of Multilayer PCB

PCB circuit boards utilize diverse substrate materials like organic (e.g., FR4, Polyimide) and inorganic (e.g., metal, ceramic), each offering unique advantages such as enhanced mechanical strength, heat dissipation, and electromagnetic shielding, crucial for high-performance applications.