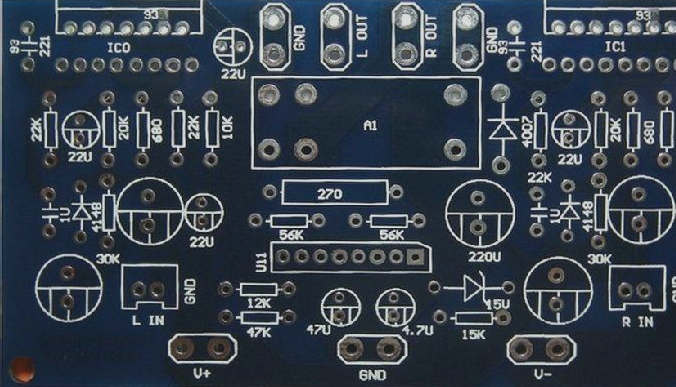

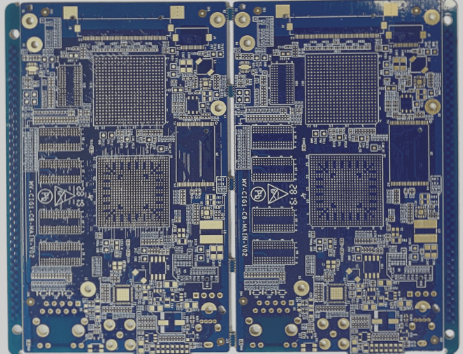

False soldering and improper soldering in DIP plug-in and PCB assembly

The rapid advancement of electronic technology has led to increasing challenges in PCB soldering, particularly false soldering, which can result in product defects that go undetected during testing, potentially damaging a brand’s reputation and causing financial losses.

False soldering and improper soldering in DIP plug-in and PCB assembly Read More »