What are the key considerations for PCB thermal design?

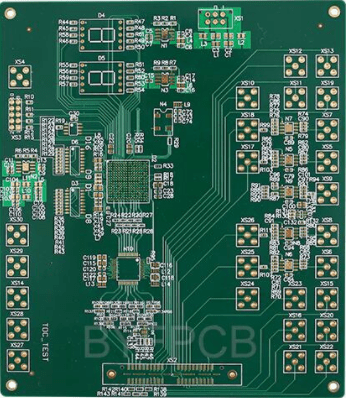

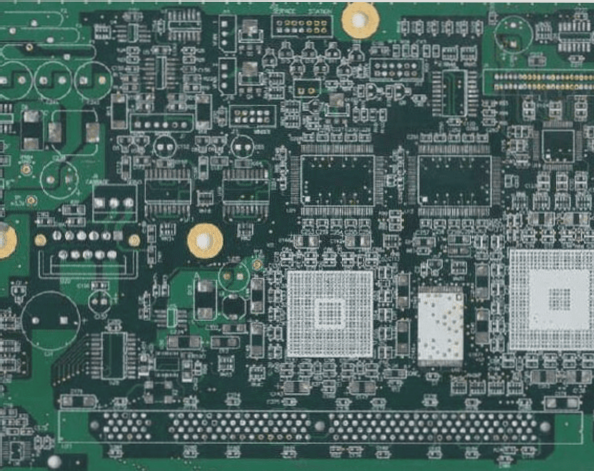

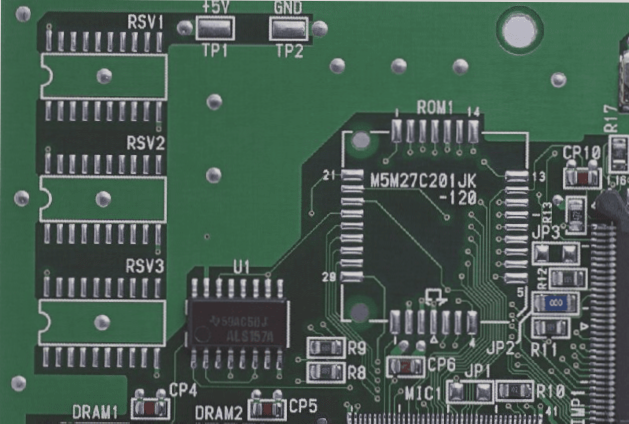

The thermal design of PCB layout involves careful component placement to manage heat dissipation, prevent overheating, and ensure reliability, with specific guidelines for component positioning, heat shielding, and optimizing airflow for effective cooling.

What are the key considerations for PCB thermal design? Read More »

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย