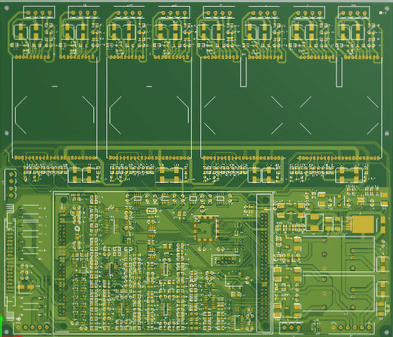

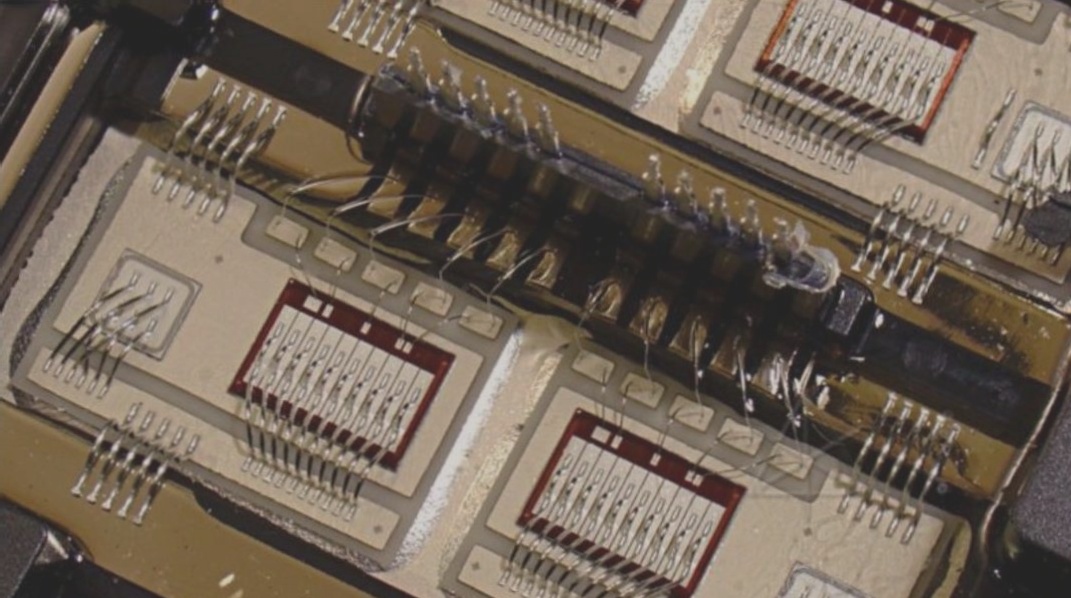

PCB soldering defects resulting from environmental factors.

Defects in soldering, such as bubbles, lack of solder, overheating, cold welding, copper foil lifting, pinhole formation, and rosin soldering, arise from various issues including thermal imbalance, insufficient solder, excessive heat, and improper techniques, each impacting joint strength and circuit reliability.

PCB soldering defects resulting from environmental factors. Read More »