What is PCB design and how are integrated circuits incorporated into it?

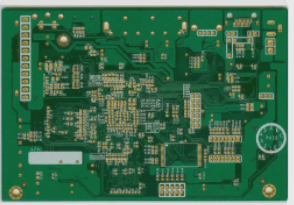

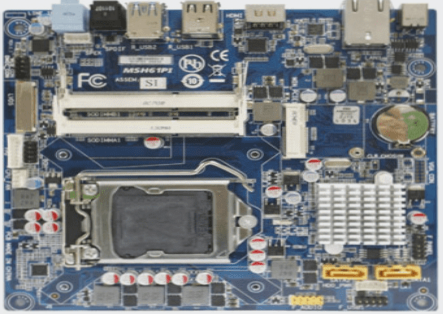

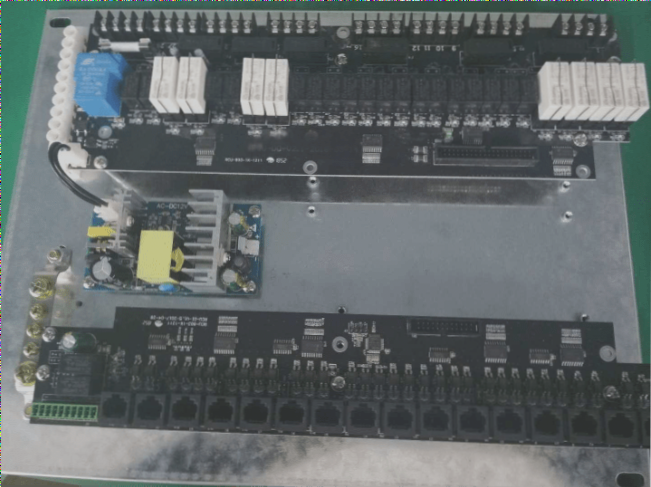

A PCB consists of several key components such as circuits, dielectric layers, holes, solder resist, silk screens, and surface finishes, providing high-density, reliable, flexible, and testable designs, while integrated circuits (ICs) are small, high-performance chips soldered onto the PCB to enhance functionality and reliability.

What is PCB design and how are integrated circuits incorporated into it? Read More »