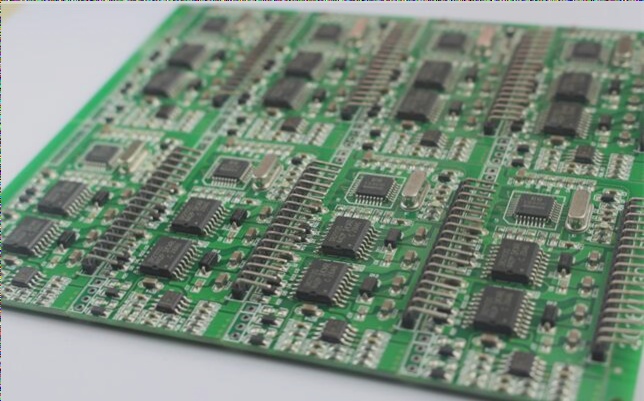

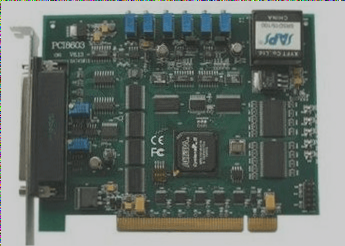

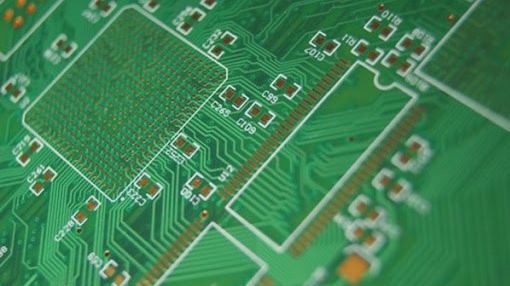

PCB circuit board color and photoresist application.

The article explains why PCB circuit boards are green, noting that the green color comes from the solder mask used for protection, and it briefly describes different types of circuit boards, including flexible, rigid-flex, and traditional PCBs.

PCB circuit board color and photoresist application. Read More »