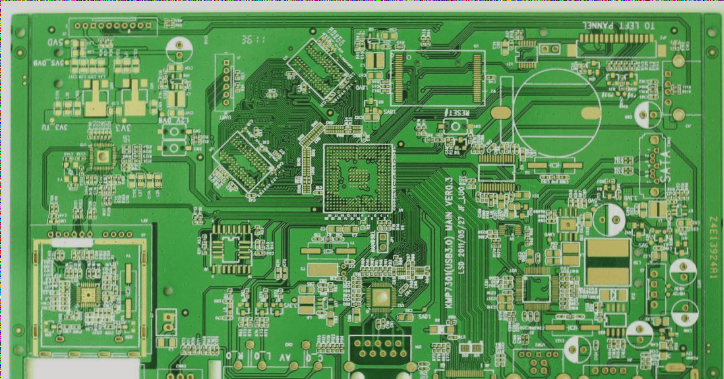

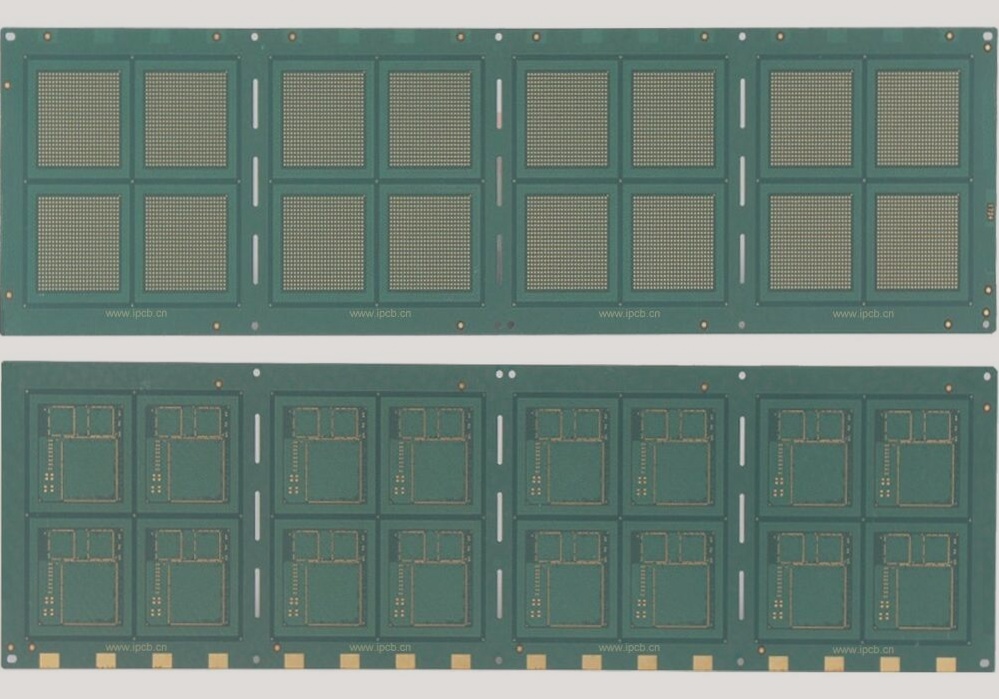

Challenges in SMT prototype manufacturing and production efficiency.

SMT prototype production faces challenges such as design complexity, component variability, solder paste application, and quality control, but these can be mitigated through advanced technologies, proactive planning, and adherence to best practices, leading to higher quality and faster time-to-market.

Challenges in SMT prototype manufacturing and production efficiency. Read More »