What are the requirements for mounting SMD components on FPC (Flexible Printed Circuit)?

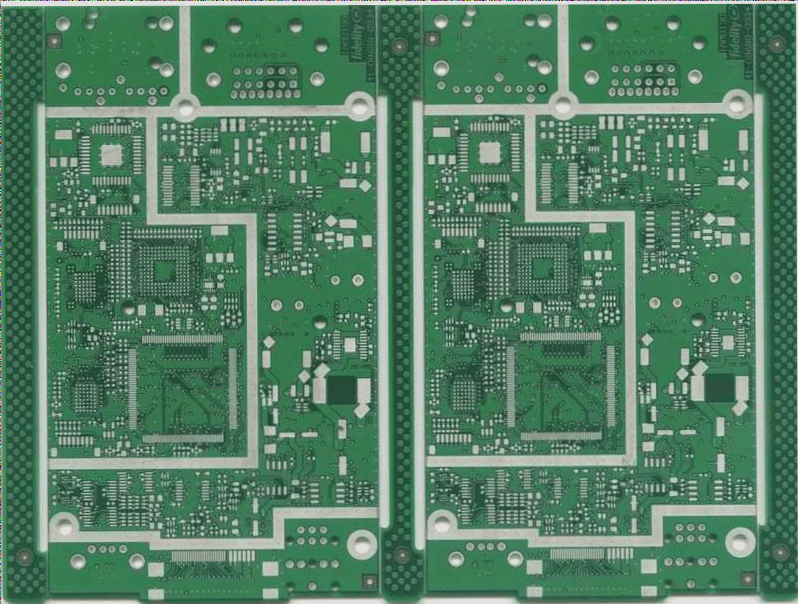

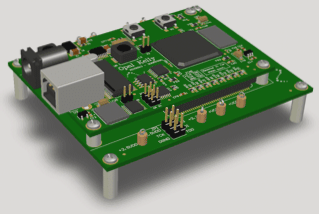

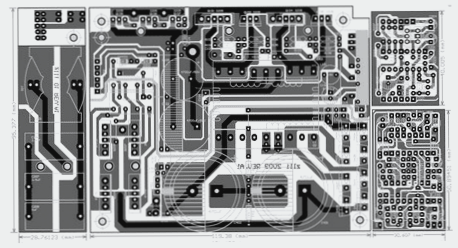

Mounting surface-mount devices (SMDs) on flexible printed circuits (FPCs) has become a key trend in miniaturized electronics, requiring precise processes like solder paste printing, accurate placement, and careful fixation of FPCs to ensure high-quality soldering and assembly.

What are the requirements for mounting SMD components on FPC (Flexible Printed Circuit)? Read More »