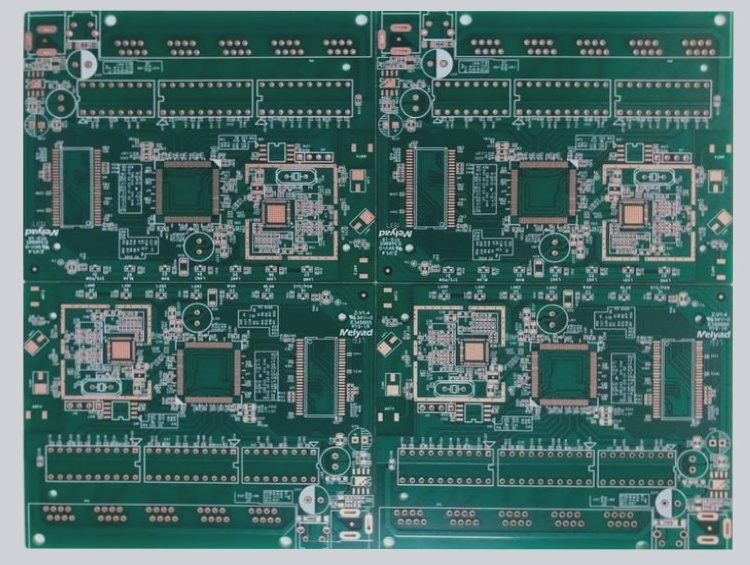

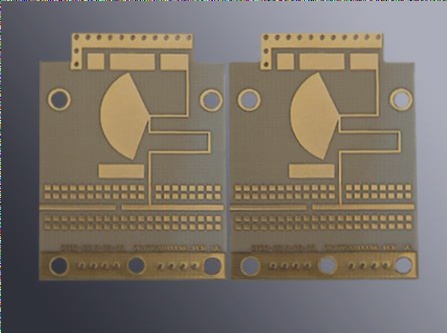

Title: Preventing Components from Dislodging During Secondary Reflow Soldering of SMT Assemblies: Part 4 Text: In our previous discussions, we delved into strategies for mitigating the risk of components dislodging during secondary reflow soldering processes. In this installment, we continue our exploration by examining additional techniques to uphold assembly integrity.

WellCircuits Limited advises against mixing high and low solder paste due to potential solder strength issues. Thorough reliability evaluations are necessary. For safer reflow, apply high-temperature paste on the first side and low-temperature paste on the second. Evaluate cost implications before re-welding, considering both post-re-welding and parts falling, and explore options like robot welding for consistency and quality.