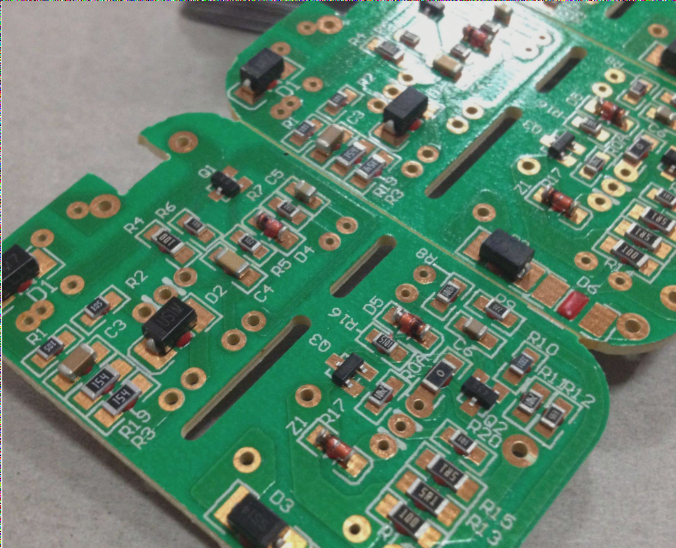

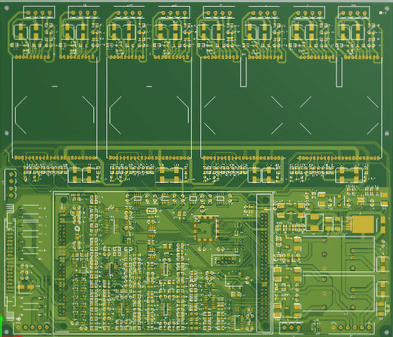

Limited understanding of tin usage in PCB circuit boards.

Poor soldering in PCB design and production can lead to various defects, often caused by issues like insufficient tinning, contamination, inadequate flux, or improper soldering temperature, and requires proper prevention strategies such as chemical analysis, pre-plating treatment, and temperature control.

Limited understanding of tin usage in PCB circuit boards. Read More »