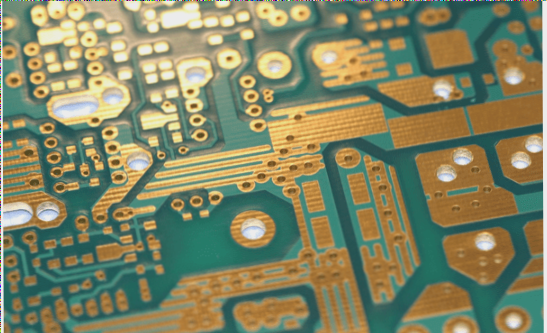

Common Causes of Incomplete Soldering in PCB Assembly Prototyping

In PCB assembly, ensuring high-quality soldering is crucial for product functionality, and incomplete soldering, often caused by poor solder paste quality, can be mitigated by using high-quality materials, optimizing processes, and controlling environmental conditions.

Common Causes of Incomplete Soldering in PCB Assembly Prototyping Read More »