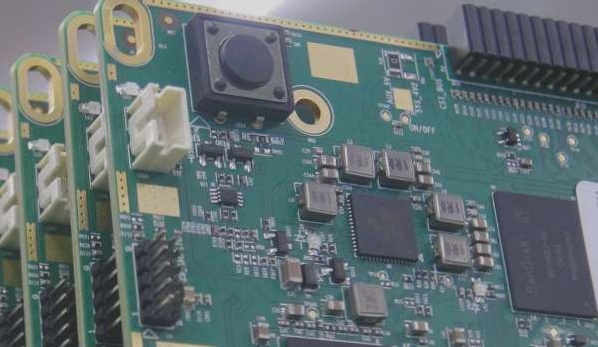

Distinguishing Between Two Methods of Attaching Components to a PCB during SMT Chip Processing

SMT and through-hole PCB assembly methods each have their own advantages and are chosen based on factors such as component size, availability, performance, cost-effectiveness, strength, and power requirements.