Solutions for Defects in PCB Circuit Board Production

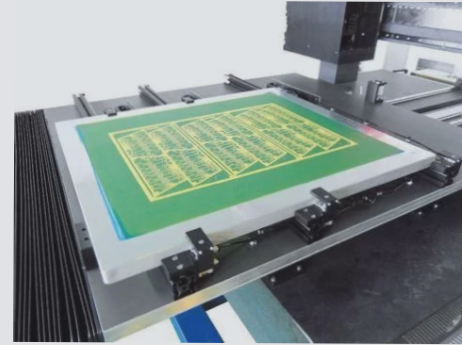

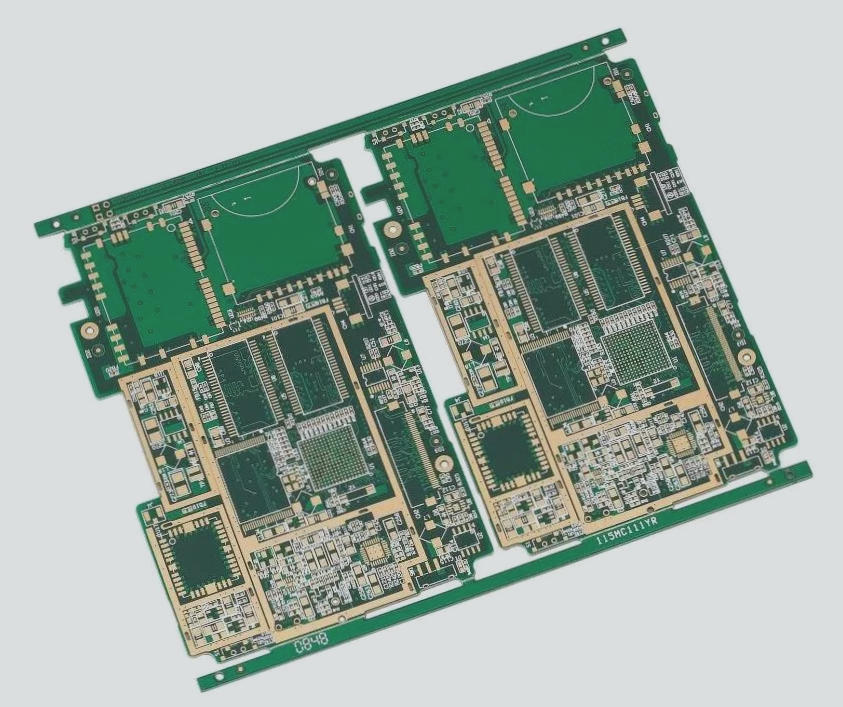

The production of PCB circuit boards involves multiple processes where quality defects can occur due to various factors, and solutions are provided for common issues like surface cleanliness and exposure time.

Solutions for Defects in PCB Circuit Board Production Read More »