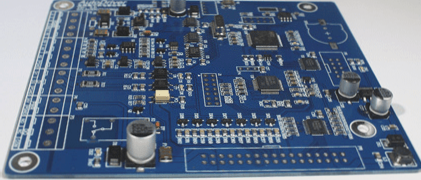

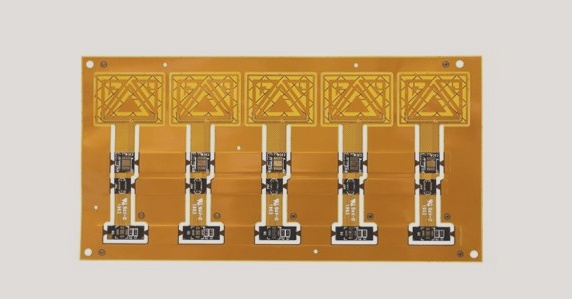

Highly practical design for high-frequency PCB circuits

In high-speed PCB design, copper coating in blank areas is typically used for grounding, and the distribution between grounding and power supply should minimize impedance effects and signal integrity issues, with test point placement often requiring manual adjustments based on density and test specifications.

Highly practical design for high-frequency PCB circuits Read More »