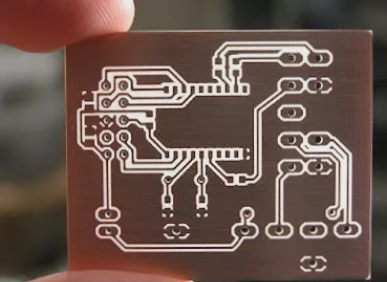

Regarding the transition from PCB schematic to layout

Key steps in transferring PCB schematics to layout include grid setup, defining blank areas and vias, adjusting pad/via parameters, establishing design rules, customizing shortcut keys, managing schematic errors, synchronizing design updates with annotation, renumbering devices, and handling last-minute changes effectively.

Regarding the transition from PCB schematic to layout Read More »