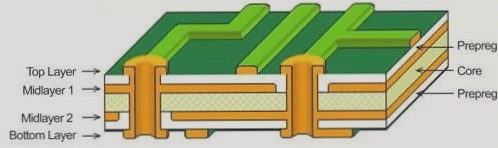

As a PCB expert, I am familiar with the common drilling methods used in PCB fabrication, including through holes, blind holes, and buried holes. Through holes allow components to be soldered to both sides of the board, blind holes are drilled to a specific depth for components that do not require connections on both sides, and buried holes are located between inner layers of the PCB. Each method has its own advantages and considerations, crucial in the design and manufacturing of PCBs. Through holes, also known as VIAs, conduct or connect copper foil lines between different layers of the circuit board, while blind holes connect the outermost circuit with the adjacent inner layer and buried holes are links between circuit layers inside the PCB that do not extend to the outer layer. These drilling methods are essential for high-density, high-precision PCBs in the rapidly evolving electronics industry.