What are the consequences of lead presence on a PCB circuit board?

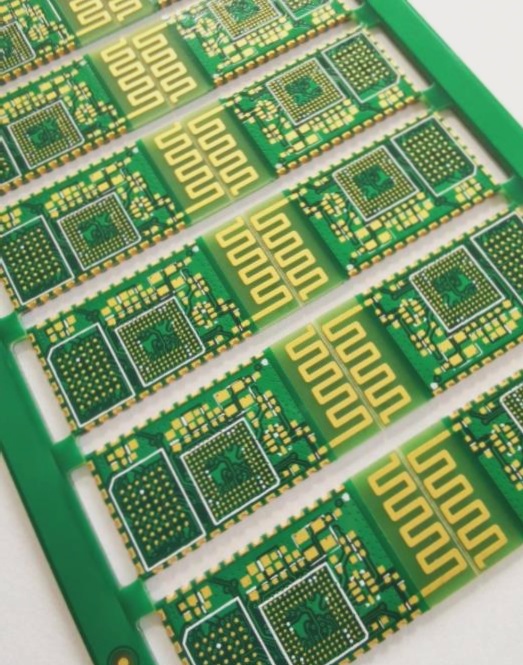

In PCB production, the shift from lead-based to lead-free soldering processes is driven by environmental regulations, performance differences, and cost considerations, with lead-free technology offering better solderability and aligning with global sustainability efforts despite higher costs.

What are the consequences of lead presence on a PCB circuit board? Read More »