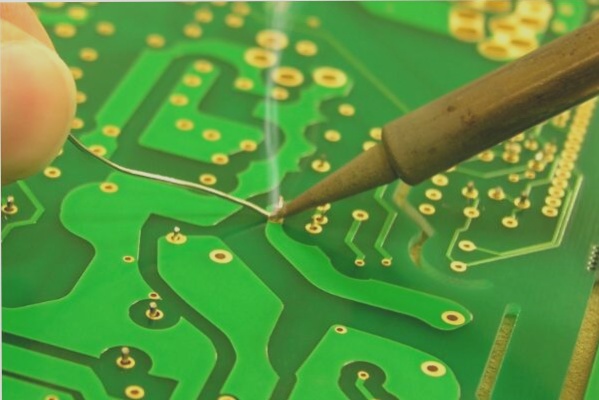

Soldering Machine Classification and Key Considerations for Selection

This article discusses the different types of soldering machines used in electronics manufacturing, including wave soldering, reflow soldering, and selective soldering, while emphasizing key operational factors like temperature control, flux selection, tool maintenance, and operator skill to ensure high-quality solder joints and reliable electronic products.

Soldering Machine Classification and Key Considerations for Selection Read More »