SMT Assembly Process 2

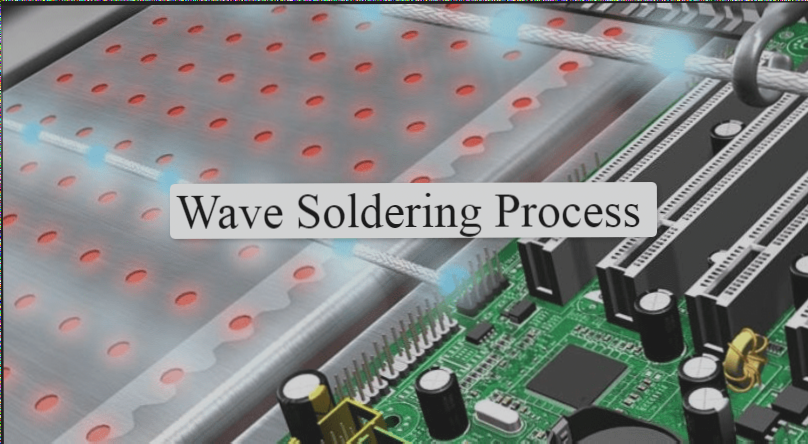

The SMT assembly process is closely related to each process step before soldering, including capital investment, PCB design, component solderability, assembly operations, flux selection, temperature/time control, solder, and crystal structure, with the most commonly used solder for wave soldering being eutectic tin-lead alloy. Temperature control and solder purity are essential for ensuring quality solder joints.