Reliability Testing of Lead-Free Solder Joints in PCBA

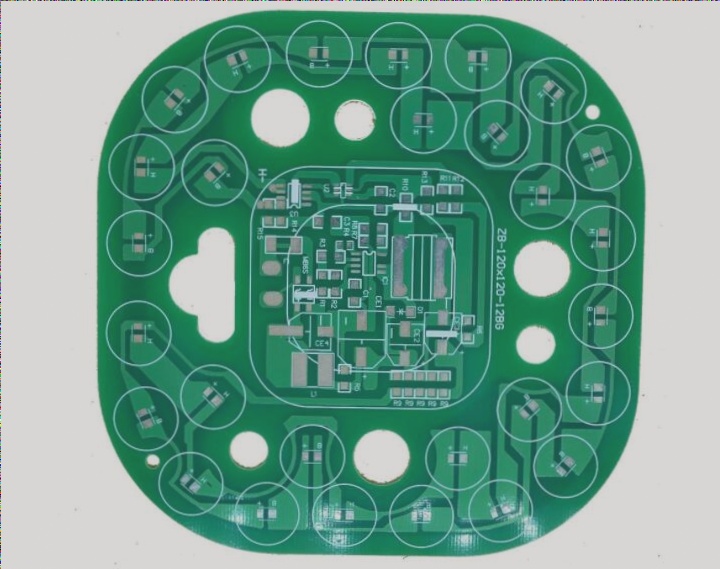

Reliability testing of PCBA lead-free solder joints involves various methods like visual inspection, X-ray analysis, mechanical stress tests, and environmental simulations to assess their durability and performance under thermal, mechanical, and environmental stresses, ensuring long-term reliability for electronic products.

Reliability Testing of Lead-Free Solder Joints in PCBA Read More »